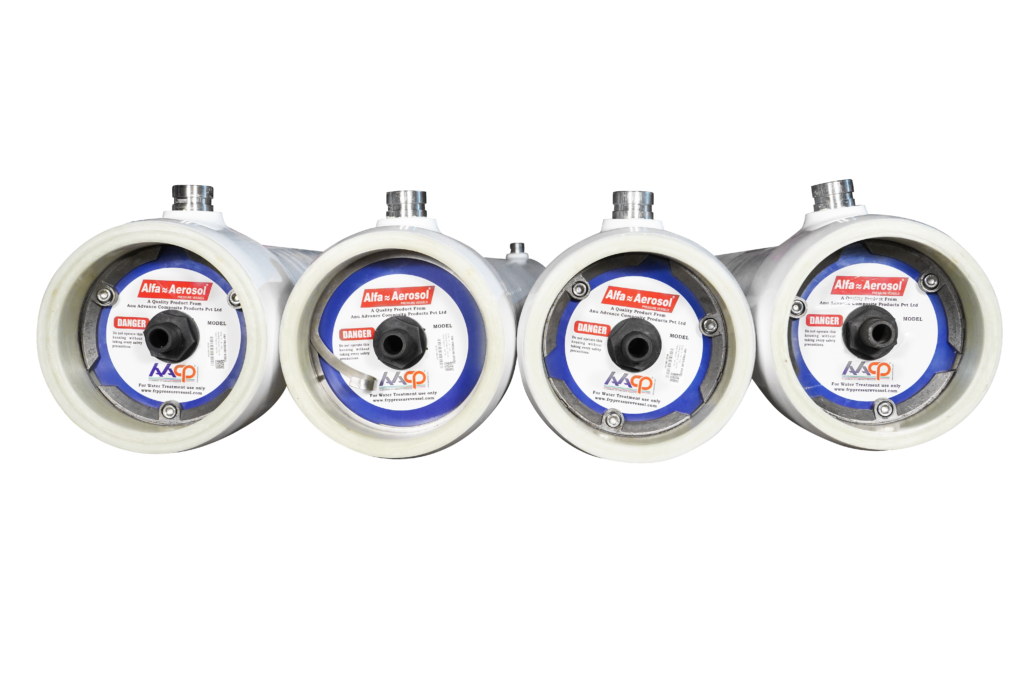

FRP Membrane Housing

FRP Membrane Housing

CERTIFIED TO NSF/ANSI/CAN -61

Looking for durable and reliable FRP membrane housings for high-pressure applications? Discover the strength and performance of Alfa Aerosol — the trusted brand of FRP membrane vessels manufactured by Anu Advanced Composite Products Pvt. Ltd., a reputed Indian composite manufacturer.

Sahara Industry, a leading name in the water treatment and process equipment industry, proudly promotes Alfa Aerosol as part of its extended group of companies.

🌟 About the Manufacturer

Anu Advanced Composite Products Pvt. Ltd. is an ISO-certified manufacturer of high-quality composite membrane housings, supplying both domestic and international markets. With a legacy of engineering excellence and advanced production technology, Anu ensures each RO membrane housing meets global performance standards.

Sahara Industry, the sister concern, handles national and international sales and technical support, offering clients end-to-end solutions in water and wastewater treatment.

Technical Highlights

Material: Reinforced Epoxy/Fiberglass Composite

Liner Material: High-grade epoxy resin for chemical and pressure resistance

Operating Pressure Range: 300 PSI to 1800 PSI

Operating Temperature: Up to 49°C (120°F)

Burst Pressure: Up to 4X of rated pressure

Design Life: 10–20 years under normal conditions

End Connections: SS316, PVC, or customized as per request

Mounting: Available with Saddle, Clamp, and Skid options

Finish: UV-resistant, glossy white or custom-colored finish

💡 Key Features & Benefits

✅ Lightweight yet robust FRP body for easy handling

✅ High resistance to chemicals, pressure, and temperature

✅ Mirror-smooth internal surface for minimal pressure loss

✅ Modular design for multi-element assemblies

✅ Custom options available

SAHARA INDUSTRY PRESSURE VESSELSDROPLET MEMBRANE HOUSING

- Pressure Vessels PAPV Series

Sahara Industry has over 20 years of experience as a global provider of top-quality membrane pressure vessels that are specifically designed to allow RO membranes to withstand high pressure water treatment applications. These pressure vessels are reinforced in fiberglass housings, which greatly increase the strength and durability of the membranes.

Membrane pressure vessels are designed for constant use as a housing for membrane elements. Vessel has been designed to meet the standards of the American Society of Mechanical Engineers (ASME), Boiler and Pressure Vessel Code, Section X. At an additional cost, vessels can be checked during fabrication by an ASME Authorized Inspector and Code stamped. Sahara Industry stocks a large quantity of 2.5″, 4″ and 8″ membrane pressure vessels that range in pressure from 300psi all the way up to 1000psi for high pressure membrane systems. Each membrane pressure vessel comes with mounting pads, straps, hardware and also both end caps. All of the membrane pressure vessels offered by Sahara Industry are capable of handling even the harshest of conditions. Alfa Aerosol, Osmotech are all product lines that Sahara Industry stocks and offers its customers.

Water treatment systems depend on the provision of secure, long-lasting, and clean membrane pressure vessels as housings for their elements. The membrane pressure vessels within Sahara Industry’s listings are capable of filtering using reverse osmosis or NF treatment or other types of filtration systems. These vessels maintain the texture and conciseness resilience that Sahara Industry dreams up to.

Advantages Of FRP Membrane Housing

The membrane housing is by far one of the most vital parts within the reverse osmosis system process and our pressure vessels are designed to provide maximum performance in protecting your membrane. The features down below exemplify the benefits of our membrane pressure vessels and their ability to handle the highest pressures necessitated for reverse osmosis.

- Approved designing by the USDA for clean filtration

- Provided in different sizes of diameters and lengths

- Huge sanitary guarantee maximum flow

- Product hold-up is eradicated by sophisticated welds

- Available in both high and low pressures PSI units

- Low operational cost

- Industrial applications are provided with non-sanitary housings

More compact and easier to use than PVC and SS housings with similar pressure ratings

Our Clients

High-Quality Water Treatment Solutions For Various Industries